UPDATES

If you download any of my worksheets, you might want to check back from time-to-time to see if I have made any revisions. If you send me an email specifically requesting to be notified of revisions, I will do so. I will NOT send you any communication you have not specifically requested.

DISCLAIMER

These worksheets are distributed at no charge on an as-is basis. The author does not assume any liability for their use.

WORKSHEET PROTECTION AND COPYRIGHT

Fisher Control Valve Sizing Software Firstvue Download Adobe. Fisher Firstvue Download; Control Valve Sizing Software; Go to 1 2345Next page. Author: Binary Pros. License:Freeware (Free) File Size:6.51 Mb. Runs on: Win95, Win98, WinME, WinNT 3.x, WinXP, Windows2000, Windows2003. Compressed File System Sizing Tool v.0.1. The Compressed File System Sizing Tool scans a directory and outputs the size, the compressed size, and the type of each file in the tree.

I have protected the worksheets to prevent accidental changes to the formulas and calculation method. It is still possible to see the formulas that are used so that those who are interested can verify the calculation method, or use my calculation methods and formulas in their own worksheets or other programming environments.

Fisher Control Valve Sizing Software Firstvue Download Windows 10

If you want to make changes to the worksheets, the password is eliminator, but you do so at your own risk. Note that some of my newer worksheets, though protected to prevent accidental changes, do not require a password. For those newer sheets, simply select from the Excel Review menu, Unprotect sheet.

I have not claimed copyright to these worksheets because I want them to be used by anyone who wants to use them. If you design your own worksheets or other program using my formulas and calculation methods, leave my name off, as I don’t want credit for any possible incorrect calculations.

ControlValve Sizing application workbooks

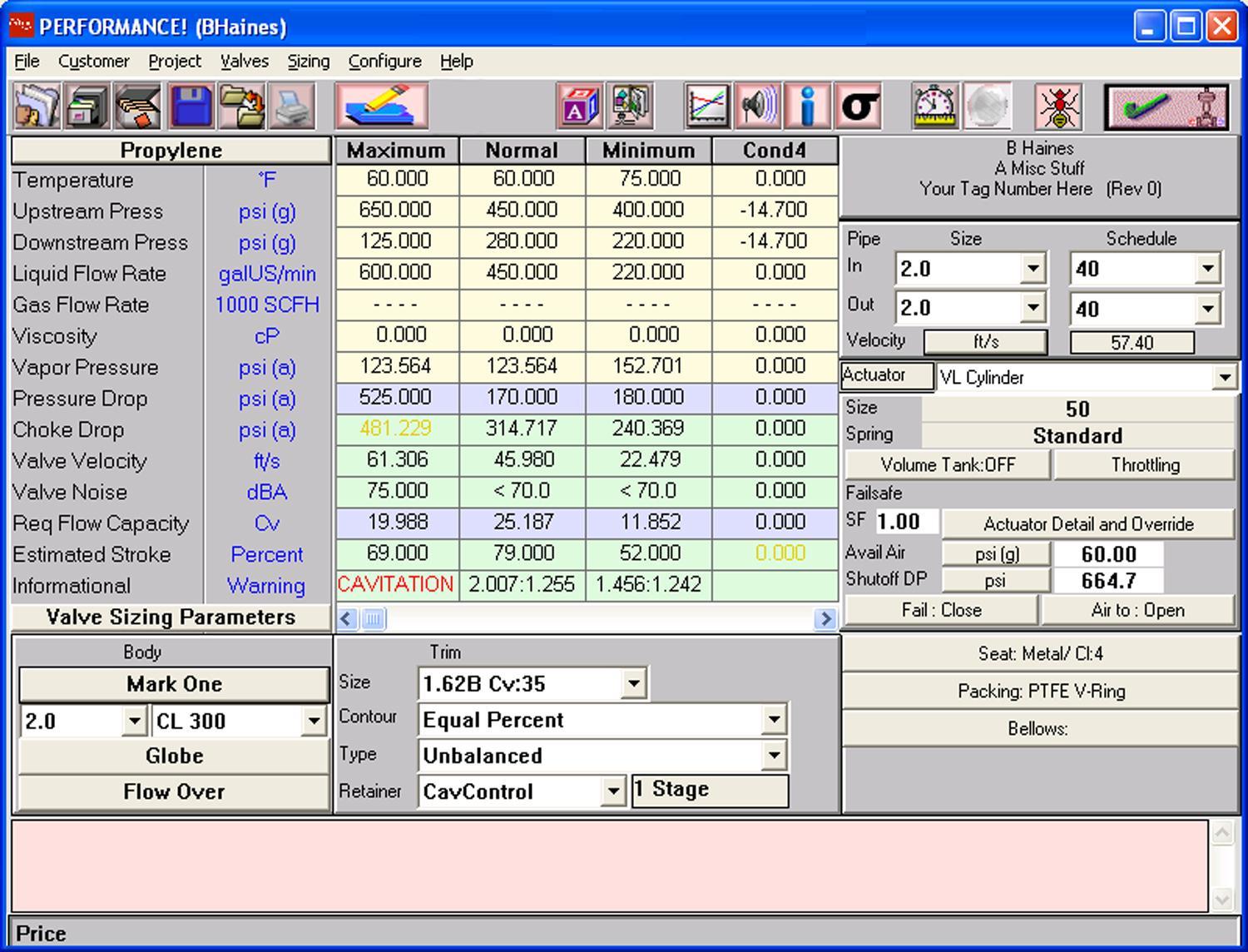

These Excel® Workbooks are intended as full function control valve sizing applications.

They include control valve sizing calculations in accordance with the current ISA/IEC standards and noise calculations in accordance with the current IEC standards. These workbooks include typical valve sizing and noise calculation parameters and typical tables of valve capacity (Cv) for a number of the most popular control valve styles. As such, many users will find them suitable for preliminary control valve selection. When you select a valve manufacturer it would be wise to ask them to verify your selections based their proprietary parameters.

Additional features rarely found in valve selection applications is the ability to calculate and graph the install flow characteristic and installed gain of a particular valve style and size in the system into which it is to be installed.

There are three workbooks. Gas flow in mass flow units, Gas flow in volumetric flow units and Liquid flow. The first tab on each is a “READ ME” tab which contains an instruction manual. Reading the manual will significantly improve your experience with the workbook.

I have retained my original stand-alone worksheets for valve sizing and IEC noise that are below for those who prefer to use them.

The download is a zip file which contains a short instruction manual, and Excel® worksheets for:

Liquid (Volumetric flow units) Includes a tab that can convert mass flow to volumetric flow

Gas (Volumetric flow units where the molecular weight or specific gravity is known)

Gas (Mass flow units where the density is known. This includes steam.)

A unique feature of these worksheets is that in addition to performing traditional Cv calculations, they can also graph the installed flow characteristic and installed gain of a valve when it is installed in a particular system.

These worksheets are based on ANSI/ISA-75.01.01 (IEC 60534-2-1 Mod) -2012 'Flow Equations for Sizing Control Valves.' Each has space for four simultaneous calculations. For example, you can calculate required control valve capacity (Cv or Kv) for Minimum, Normal, Maximum and one additional flow condition. Engineering units are by default set to US units, but can be easily changed to SI units. Your experience with these worksheets will be much better if you read the included 'Instructions.'

4-27-18: Minor revision to liquid sizing worksheet. No obvious difference, no change to calculated results. See Revision History..

This worksheet graphs a control valve’s installed flow and installed gain. It does this in conjunction with the user’s preferred control valve sizing software. This is the worksheet that was presented in the March 2021 issue of P.I. PROCESS INSTRUMENTATION magazine. A copy of the article can be downloaded from the Links page of this web where it is listed as: “Graphing Installed Flow and Gain of a Control Valve.” The article describes how to use the worksheet.

I have recently become a member of the ISA S75.07 committee that is working on standards involving control valve noise. So far my main effort has been to make Excel®worksheets that calculate Aerodynamic and Hydrodynamic noise in accordance with the current IEC Standards. These calculations involve many equations and, in the words of Dr. HansBaumann area'programmers nightmare.' I have to agree with him!

Here are two zip files, one for Aerodynamic noise and one for Hydrodynamic noise. Each contains a worksheet for flow in mass flow units and a worksheet for volumetric flow units. Also included for each is a short instruction file.

On 1/15/18 I replaced the Hydrodynamic noise file withRev. 1b. The only change is that I added the option of either entering a known value of xFz or letting the worksheet calculate an approximate value using Equation 3 of the Standard.

On 3/9/18 I added an Excel sheet that calculates typical values for some parameters required by the IEC noise calculations.

On 8/7/18 I replaced the Aerodynamic noise sheets with Rev. 2. There was a minor error in the FLP calculation for Conditions 2, 3 and 4. This only resulted in a calculation error of about 1 dB(A).

On 10/7/18 I replaced the Typical xFz, Fd and FL parameters worksheet with Rev 3. There was a change to the FL calculation for the Globe 4 port cage valves.

On 10/9/18 I replaced the Typical xFz, Fd and FL parameters worksheet with Rev 4. There was a change to the xFz calculation for the Globe 4 port cage valves.

New 10/28/19

Fisher Control Valve Sizing Software Firstvue Download Free

This Excel sheet calculates the speed of sound in gas.

This worksheet approximates liquid vapor pressure for control valve sizing purposes. The calculation uses the Antoine equation along with Antoine parameters as presented on the 'NIST Chemistry WebBook.' The worksheet includes a link to the NIST Chemistry WebBook, along with instructions for using the worksheet.

On Aug. 31 2015 I replaced the original worksheet with Rev 1a which allows temperature input in either degrees C or F and returns vapor pressure in both bar and psia.

Revised May 6, 2017. Minor revisions to some tabulated data. Added a README (Information and Instructions) tab.

Revised May 28 2017. Minor corrections to some tabulated values. Added tabulated values for Tr = 2.5 for increased accuracy.

This worksheet approximates the compressibility factor of gasses for control valve sizing purposes. It uses tabulated data from the Nelson Obert charts with two dimensional interpolation between the tabulated reduced pressure points and reduced temperature points.

It is valid for reduced temperatures (Tr) between 1.0 and 15 and reduced pressures (Pr) between 0.0 and 20. The worksheet shows the reduced pressure and temperature being used in the calculation, and informs the user whether each is within the limits of the worksheet.

There is space on the worksheet for four calculations to make it easily compatible with the four calculations performed by the above control valve sizing worksheets.

This worksheet approximates the behavior of P1 and P2 (pressure upstream and pressure downstream of a control valve) at different flow rates. This might be useful if valve Cv calculations need to be made at several flow rates, when only P1 and P2 are known at the maximum and minimum design flow rates. The principle behind the calculation is that pressure loss in a piping system is approximately proportional to flow squared.

Although the units on this worksheet are shown as gpm and psig, the calculation method is independent of units and the user can use any appropriate units.

Fisher Control Valve

On 8/20/15 I replaced Revision 1 of the file with Revision 2, which reformats the worksheet to allow entry of any minimum design flow and adds an Instruction tab and a Calculation Method tab.

This worksheet calculates the pressure drop in liquid piping systems.

There are ten columns of identical individual calculations. You can use just one, or you can use more than one for different flow rates in the same system, for unrelated calculations or for chained calculations for the same system where you want to break the system down into several small systems in series.

There is a description of how the worksheet works and instructions for its use on the second tab.

On 5/21/15 I added a third tab with typical isolation valve Cv values.